Nutsert 3/8-16 AtS2-616

| Thread Size | PN |

|---|---|

| 3/8-16 UNC | ATS2-616 |

Overview

|

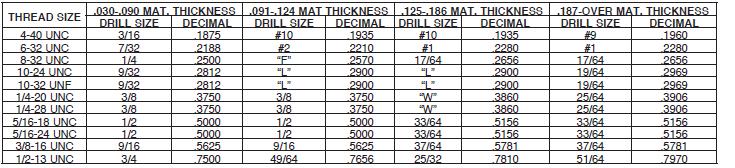

Installation hole size for the A-T Series Insert is determined by the parent material's thickness and density. The thicker the material the larger the hole required to allow full 360° installation swaging. The application should be tested before hole size is specified. The A-T Series Insert is unique in that it can be installed into most any material above .030/,76 mm in thickness. As the A-T Series is installed, the threaded portion is completely swaged 360° into the sleeve portion and the hole. This permits the A-T Series to be used with Grade 8/metric 12.9 mating screws. The A-T Series Insert is installed using lightweight, hand held pneumatic tools that can be located at any position in your product's assembly sequence. The A-T Series Insert can be installed either prior to or after finish. 360°SWAGING HOW IT WORKS FOR YOU As the A-T Series Insert is installed, the threaded nut portion is drawn into the upper sleeve portion.As this occurs, a 360° swaging action takes place anchoring the A-T Series in the parent material. |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Reference Chart

| Thread Size | .030-.090 Mat. Thickness | .091-.124 Mat. Thickness | .125-.186 Mat. Thickness | .187-Over Mat. Thickness | ||||

| Drill Size | Decimal | Drill Size | Decimal | Drill Size | Decimal | Drill Size | Decimal | |

| 4-40 UNC | 3/16 | .1875 | #10 | .1935 | #10 | .1935 | #9 | .1960 |

| 6-32 UNC | 7/32 | .2188 | #2 | .2210 | #1 | .2280 | #1 | .2280 |

| 8-32 UNC | 1/4 | .2500 | "F" | .2570 | 17/64 | .2656 | 17/64 | .2656 |

| 10-24 UNC | 9/32 | .2812 | "L" | .2900 | "L" | .2900 | 19/64 | .2969 |

| 10-32 UNF | 9/32 | .2812 | "L" | .2900 | "L" | .2900 | 19/64 | .2969 |

| 1/4-20 UNC | 3/8 | .3750 | 3/8 | .3750 | "W" | .3860 | 25/64 | .3906 |

| 1/4-28 UNC | 3/8 | .3750 | 3/8 | .3750 | "W" | .3860 | 25/64 | .3906 |

| 5/16-18 UNC | 1/2 | .5000 | 1/2 | .5000 | 33/64 | .5156 | 33/64 | .5156 |

| 5/16-24 UNC | 1/2 | .5000 | 1/2 | .5000 | 33/64 | .5156 | 33/64 | .5156 |

| 3/8-16 UNC | 9/16 | .5625 | 9/16 | .5625 | 37/64 | .5781 | 37/64 | .5781 |

| 1/2-13 UNC | 3/4 | .7500 | 49/64 | .7656 | 25/32 | .7810 | 51/64 | .7970 |

| Thread Size | Thread Call Out | HD ±.005 | L ±.015 | D Max. | IL Max. | LB ±.015 | ILB Max. | IATD** Max. | Hole Depth Min. | Part No. |

| 4-40 UNC | 440 | .211 | .370 | .1875 | .205 | .660 | .495 | .395 | .400 | ATS2-440 |

| 6-32 UNC | 632 | .240 | .370 | .2185 | .205 | .675 | .505 | .410 | .400 | ATS2-632 |

| 8-32 UNC | 832 | .269 | .370 | .2495 | .205 | .675 | .505 | .410 | .400 | ATS2-832 |

| 10-24 UNC | 1024 | .306 | .370 | .2805 | .205 | .685 | .520 | .385 | .400 | ATS2-1024 |

| 10-32 UNF | 1032 | .306 | .370 | .2805 | .205 | .685 | .520 | .385 | .400 | ATS2-1032 |

| 1/4-20 UNC | 420 | .400 | .515 | .3745 | .275 | 1.005 | .760 | .615 | .540 | ATS2-420 |

| 1/4-28 UNC | 420 | .400 | .515 | .3745 | .275 | 1.005 | .760 | .615 | .540 | ATS2-428 |

| 5/16-18 UNC | 518 | .528 | .615 | .4995 | .325 | 1.065 | .770 | .630 | .640 | ATS2-518 |

| 5/16-24 UNC | 518 | .528 | .615 | .4995 | .325 | 1.065 | .770 | .630 | .640 | ATS2-524 |

| 3/8-16 UNC | 616 | .588 | .745 | .5615 | .390 | 1.450 | 1.095 | .890 | .770 | ATS2-616 |

| 1/2-13 UNC | 813 | .800 | .935 | .7485 | .485 | NA | NA | NA | .960 | ATS2-813 |

Documents

Reference Chart

Reviews

Great worked perfectly!

Nutsert 3/8-16 AtS2-616

Excellent service

In my opinion, these nutserts are the best threaded inserts you can buy. It’s also really nice that there is an economy tool to install that doesn’t break the bank.

In my opinion, these nutserts are the best threaded inserts you can buy. It’s also really nice that there is an economy tool to install that doesn’t break the bank.

So glad I discovered Airplane Spruce! Able to purchase what I needed, not some bag of 100. Thanks!

received everything ordered in a timely fashion

Quality product. Great service.

I installed 12, 6-32 nutserts in 0.062 in wall, aluminum tubing to repair stripped threads. Worked great. Used nutsert tool to install these and it worked great also. Installed nutserts feel strong and give much more thread engagement. Nutsert protrudes a little bit above tubing surface when installed. I filed and polished them down to make them flush. This did not seem to degrade the installation.

Received as ordered. One of few companies that follow up with their customers. Will continue to do business with them.

Easy to install and quite strong.

FREE Shipping

FREE Shipping