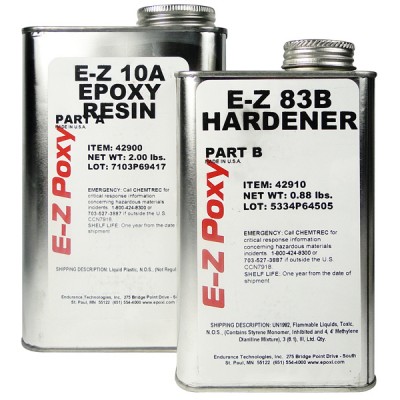

EZ Epoxy EZ83-1/2G Hardener

MFR Model# 42720

| Description | Part No. |

|---|---|

| E-Z Poxy 1/2 gal. hardener (EZ-83) 3.5 lbs | 01-00247 |

Overview

|

In early 1996, Composite Design Co. developed E-Z Poxy to provide a replacement epoxy system for Epolite (Safe-T-Poxy) which is no longer produced by Hexcel. The E-Z Poxy series of laminating systems utilizes one resin and your choice of three hardeners for varying pot life and viscosity requirements. The E-Z Poxy systems offer the same handling and physical properties as the discontinued Epolite systems including ease of use, long pot life, rapid cure for demold or process continuation, and superior room temperature curing properties. Excellent for use in sport aviation, marine, and industrial applications. E-Z 83 hardener is equivalent to Safe-T-Poxy standard hardener, and E-Z 87 is equivalent to Safe-T-Poxy slow hardener. E-Z Poxy products should not be mixed with materials produced by other epoxy manufacturers. E-Z Poxy systems provide excellent room temperature curing systems for hand layup of composite parts and tooling. The systems are designed to provide ample working time with the varied pot life options while providing a rapid finish cure. Post curing these systems will increase their physical properties as designated in the above data, however, post cure is not required. Containers are filled by weight. Cans may be short filled. |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Specifications

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Documents

- Technical Data Bulletin (PDF)

- EZ Poxy II Resin MSDS (PDF)

Reviews

I like this epoxy, especially the low odor and well-behaved cure. BTW, you can use the convenient West pumps with EZ Poxy as follows. My measurements showed that the West large pump delivers about 0.66 fl. oz. of resin per full stroke. The 207/209 hardener pump delivers about 0.22 fl. oz. per full stroke mixing this with the resin squirt yields a total of about 0.88 fl. oz., with a resin to hardener volume ratio of about 2.95. The 205/206 pump delivers about 0.12 fl. oz. of hardener per full stroke mixing this with the resin squirt yields a total of about 0.78 fl. oz., with a resin to hardener volume ratio of about 5.45. The recommended EZ Poxy resin/hardener volume ratio is 100/47 = 2.13. Two strokes of the resin pump and three strokes of the hardener pump yields a mix ratio of 1.32/0.66= 2.00, which is close to the recommended 2.13. If you want to be closer to the recommended ratio, use 2.1 strokes of the resin pump to 3 strokes of the hardener pump, which yields a volume ratio of 1.39/0.66= 2.11.

I was disappointed when the web stated it was out of stock, but I received the order a couple of days later anyway. EZ-84, now 83, IIRC, is what 95% of my Velocity is constructed with.

easy to use. Ive been using it in temperatures just over 90 degrees, the pot life is a little less than two hours at this temp but I still have lots of time to get everything laid up how I want to. The cure time at this temp is less than 24 hours.

Awesome product. works well on my aircraft project.

Awesome Epoxy for the Aircraft I am building. Have to know your amounts and weights.

Perfect for student projects.

Its the only product we use for students to complete their composite projects. Hardener just needs some heating during the winter.

I built my entire cozy IV using E-Z Poxy with EZ 83 hardner except for the fuel tanks I used the more fuel resistant slow hardner. It works great and is consistent plus it was always available to buy unlike some of the other systems.

E-Z POXY is the only resin I have used for Lay-Ups and structural work on my Velocity. I use the pump and have it set at 100-47. If the shop is at 70 degrees it will set up in 18-24 hours with the EZ 83 hardener. It is easy to mix by it’s self or add Micro Balloons, Flox or Milled Fiber to mixed resin. On big jobs I use a carbon mask to not take in the fumes. It is cut able with a knife at 18 hours sanding 24-36 hours. I find the when mixed with Milled Fiber you need to let set for 36 hours or the sanding paper plugs up. The use of a heat gun really get it flowing if needed. It starts to get thicker in about 30 minutes so heat with the gun and flow out. I really like working with the stuff.

Q&A

Please note, Aircraft Spruce ®'s personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce ® assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

This should cover approximately 184 sq yards.

A common solvent for cleaning up un-cured epoxy is Acetone. We also offer a non-hazardous cleaner called Replacetone. It is offered in quarts, 01-08823, & gallons, 01-08834.

Per the information on the Specifications Tab, the ratio is 100/44 by weight, or you can also measure it 100/47 by volume.

Any laminating epoxy can be used with this, and any fiberglass cloth we offer. If you are building an aircraft, you will want to use whatever the designer, or kit manufacturer suggests.

Yes, the resin is clear, but the hardener is amber color, and gets darker as is gets older.

Yes, our E-Z Poxy line of products are the most fuel resistant epoxy systems we offer. E-Z Poxy has a long history of use in the aviation industry, being originally developed for the Long-EZ kit aircraft. Of the Hardeners, E-Z 83B, 87B and 92B are almost identical with only a slight variation in accelerator to help vary gel time. This series of hardener has undergone long term fuel resistance studies, being exposed to diesel (containing 5% bio diesel), gasoline (containing 10% ethanol) and strain solvents (50/50 isopropyl/xylene blend). The differences in fuel resistance between these 3 should be negligible. E-Z 10A/83B is a great option for integral fuel tanks.

It can ship via ground ORMD without haz mat fees. It is hazardous for air shipping.

Yes, this is considered hazmat material for air shipping.

The West system pumps (part # 01-00318) will fit but they ratios may not be correct. If you just want to pump from the can they will work.

FREE Shipping

FREE Shipping