SAME DAY SHIPPING ON ORDERS PLACED BY 4 PM | 877-4-SPRUCE

Baileigh One Phase Power Hammer

$30421.00/Each

Part# 12-02645

MFR Model# 1005578

MFR Model# 1005578

Overview

|

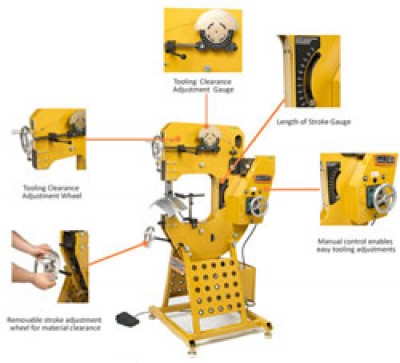

The MH-19 power hammer is a 220 volt single phase machine has the ability to transform itself from a rigid style like a Pullmax® style machine, to a spring slapping style like a Yoder® style machine, or even a very heavy duty English wheel.

When operating in the rigid mode, there is no "give" between the die heads. Used for short stroke shaping, flanging. Tooling designs and profiles are endless, but some of the options are mechanical shrinking, stretching dies, flanging dies, and louvers. The spring setup with "Throw the die" causing a dead blow hammering effect. When in this mode the total amount of pressure applied when the dies hit the metal is increase exponentially. This mode would be used for aggressive shrinking and planishing, many different tooling profiles can be used. |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Specifications

- Item Number MH-19

- Speed 0 – 1500 beats / minute

- Mild Steel Capacity 16 ga.

- Tooling Height Adjustment 2"

- Throat Depth 19"

- Capacity (Mild Steel) 16 ga.

- Aluminum Capacity 12 ga.

- Length Of Stroke Adj .177" – .550"

- Power 220V / 1-phase

- Shipping Weight 1,600 lbs.

- Shipping Dimensions 60" x 60" x 84"

- Specifications subject to change without notice.

Features

- Can function similar to a YODER by using a leaf spring setup to "Throw the die" causing a dead blow hammering effect. This mode would be used for aggressive shrinking and planishing, many different tooling profiles can be used.

- Can function similar to a PULLMAX by disconnecting the leaf spring and making the top lever a "rigid link" now there is no "give" between the die heads. Used for short stroke shaping, flanging. Tooling designs and profiles are endless.

- In the "RIGID" mode, tooling similar to an ECKHOLD/PULLMAX could be installed like mechanical shrinking, stretching dies, flanging dies, louvers, etc.

- Stroke lengths can be adjusted "on the fly" without changing the final stroke position of the die, the stroke will change in only up direction to bottom most position of the stroke will remain the same no matter what the stroke is set to. This is accomplished by the stroke toggle mechanism. By changing the pivot point of one of the links, the stroke can be varied. Can be adjusted in any mode while running. Stroke range is from .175" up to .550"

- An eccentric adjuster is used to adjust the upper stroke mechanism up or down, this would be used to get the correct distance between tools as well as setting the down force. Can be adjusted in any mode while running.

- The motor for controlling the system has the ability to vary the speed via foot potentiometer and the maximum speed limit can also be set. The foot control allows the user to "feather" the beats. Currently the machine will produce 1500 beats per minute, with infinite adjust-ability down to 0 bpm by means of the potentiometer foot pedal.

- The DC servo option has a very definite control as the commands to the motor are instantaneous. In the servo mode the machine can be set up to deliver a single hit or blow and return to the upper most position. Perfect for slow operation requiring lots of power at slow speeds.

- The MH-19 includes the following tooling to get you up and running quickly at no extra charge: (1) set of thumbnail shrink dies, (1) flat top die, and (1) Lower planishing die.

Q&A

Please note, Aircraft Spruce ®'s personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce ® assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

FREE Shipping

FREE Shipping