THE AVIATION SUPERSTORE FOR ALL YOUR AIRCRAFT & PILOT NEEDS | 877-4-SPRUCE

Tekton Angle Head Open End Wrench Set

Select Set:

11-Piece (3/8-1 In.) With Holder

11-Piece (3/8-1 In.) With Holder 11-Piece (3/8-1 In.) With Pouch

11-Piece (3/8-1 In.) With Pouch 16-Piece (10-27 Mm) With Holder

16-Piece (10-27 Mm) With HolderOverview

|

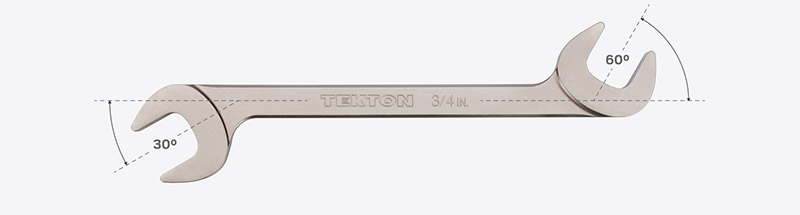

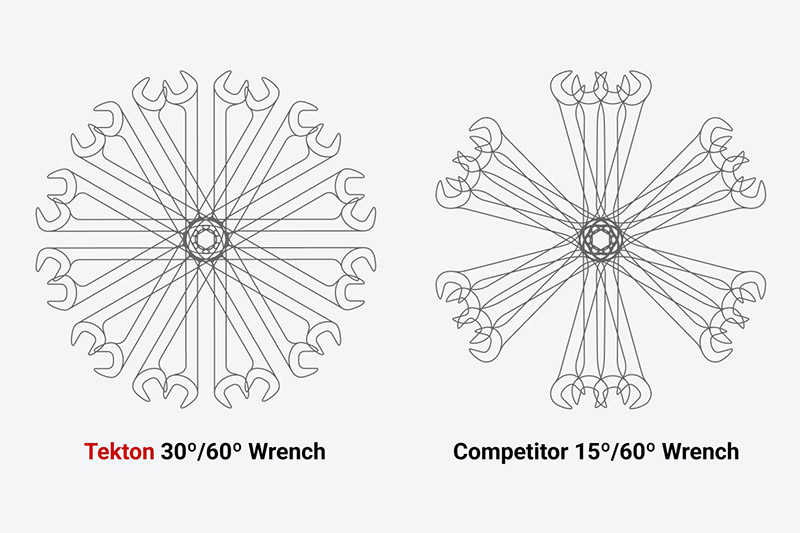

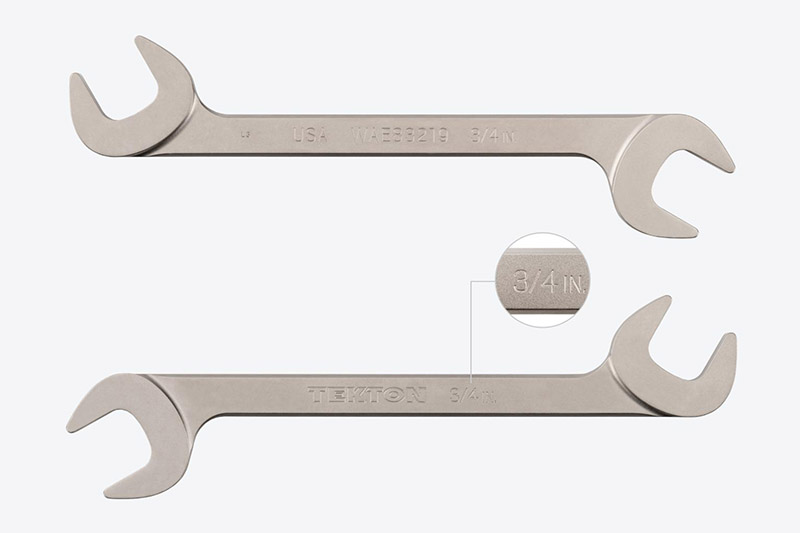

Tekton Stubby Combination Wrench Set

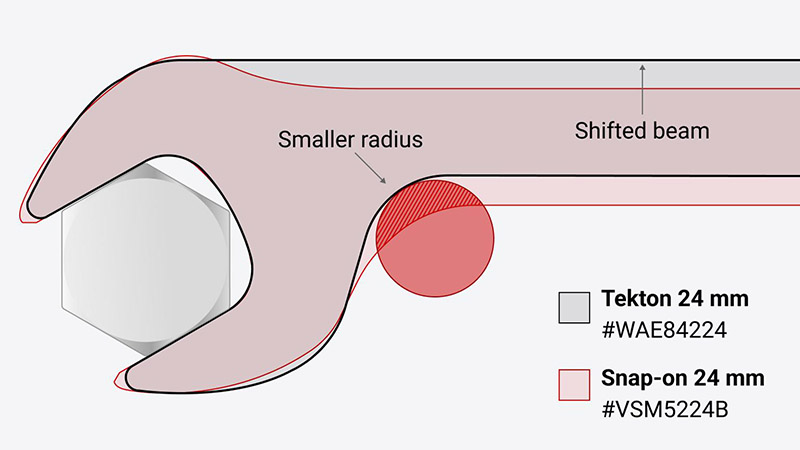

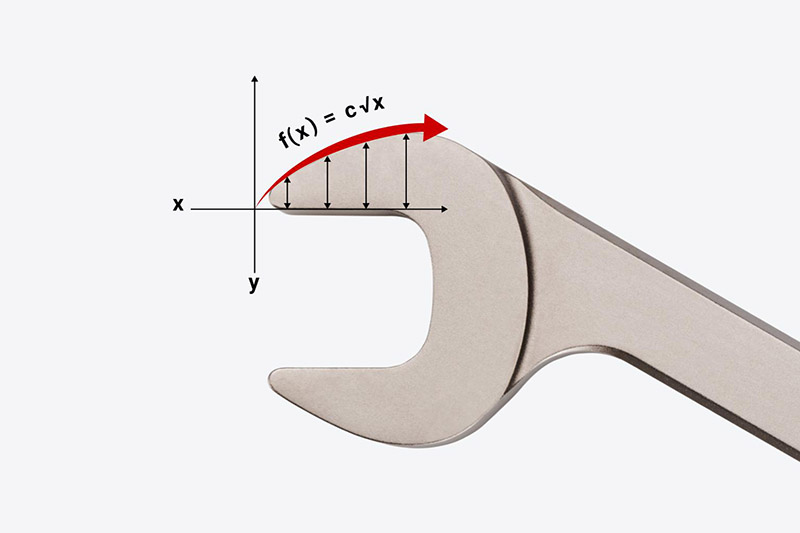

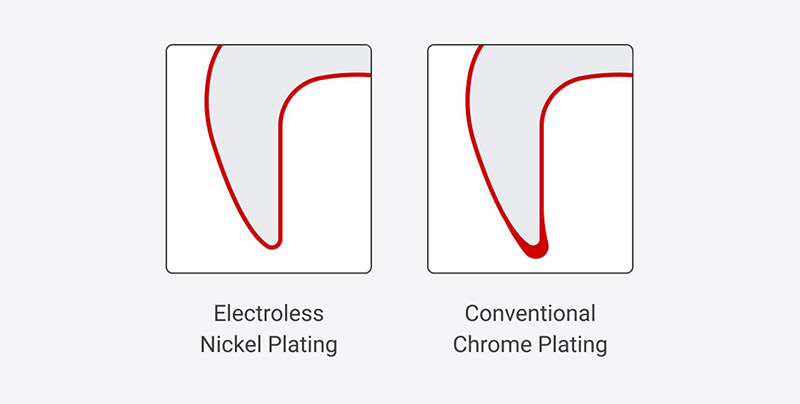

Unmatched Access Upgrade your capability to work around obstructions. With angled heads that allow you to progressively turn fasteners and fittings in confined spaces, Tekton's 30°/60° angle head wrenches save you time because you can continue work without disconnecting or dismantling equipment to access hard-to-reach areas.  Best Combination of Angles We paired 30 and 60 degree angled heads to achieve greater coverage with fewer blind spots in limited access situations.  Part of a System of Access Wrenches Tekton angle head wrenches have a 30-degree angled head on one side and a 60-degree angled head on the other for greater coverage with fewer blind spots. They complement our other access wrenches, including crowfoot, flare nut crowfoot, and service wrenches. Designed to Work in Tighter Spots Than the CompetitionBeam Position Improves PerformanceTo achieve the greatest range of motion in confined spaces, we shifted the Tekton wrench beam the maximum distance up and out of the way and reduced the radius where it meets the wrench head.  Optimized for Access and StrengthLeanest Head ShapeAt each point along its horizontal length, the height of the jaw is no more and no less than needed to achieve our strength specification, thus maximizing access.  Prevents Jaw Spread The jaw uses the largest possible inside corner radii to reduce the concentration of stress that can lead to jaw spread.  Refined DetailsMaterials and FinishWe make our angle wrenches from 4140 chromium-molybdenum steel and harden them to 50-53 HRC. The wrenches are abrasive-blasted to create a finely textured satin finish and then plated with corrosion-resistant nickel.  Clear Size Markings The wrench sizes are laser engraved onto both sides of each angle wrench with a large, permanent marking that's easy to read.  Chamfered Handle The edges of the wrench beam are chamfered to provide a smooth, comfortable grip for your hands.  Advanced Manufacturing ProcessesElectroless Nickel PlatingThe electroless nickel plating finish is easy to wipe clean and highly resistant to corrosion. Low Environmental Impact: Electroless nickel is a low environmental impact alternative to conventional hexavalent chrome plating. It uses a chemical reaction involving nickel and phosphorus and doesn't require the use and disposal of chromium. Uniform Coverage and Better Fit The electroless process applies a uniform coating to the entire tool surface. By comparison, electroplating, including conventional chrome plating, has varying thickness across the tool because the plating thickness depends on the electric current density at each point on the tool. The uniformity of an electroless coating has two major advantages:

Michigan Manufacturing Our angle wrenches are manufactured entirely in the USA with USA-made materials. Machining, engraving, vibration polishing, abrasive-blasting, and plating take place at our Grand Rapids, Michigan, manufacturing facility. |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Features

- Organization Rack:

- - Flexible Teeth Hold Wrenches

- - Full-Sized Carrying Handle

- - Fits in 2.9in Drawers

- Organization Pouch:

- - Ideal for On-the-Go - Carry angle head wrenches anywhere with the compact roll-up pouch that keeps wrenches well-packed and unable to slide out.

- - Durable Material - The polyurethane-backed 600 x 600 denier polyester is both abrasion and tear resistant, and has a Durable Water Repellent (DWR) coating.

- - Easy-Access Design - The pouch design minimizes bulk from extra material so the wrenches can be quickly accessed without any fabric flaps getting in the way.

FREE Shipping

FREE Shipping