Poly Filler Ht (High Temp)

Overview

|

Note: 3 month shelf life from date of manufacture. We suggest ordering when you are ready to use. POLY FILLER HT is a two component polyester filler paste system that provides the user both unique ease of handling and high performance characteristics when cured. POLY FILLER HT is formulated to provide a smooth creamy handling consistency and a dry tack-free surface when cured. A significant advantage of POLY FILLER HT over other materials of this type is its very low cured shrinkage. This feature allows faster application and repairs than with other filler pastes, which usually must be applied in several layers be cause of their high shrink age rate! The creamy texture of POLY FILLER HT allows for easier applying and spreading. POLY FILLER HT can be troweled to a feather edge with out rolling or skipping. It can be used to fill tiny pin holes with out lifting. The dry, tack-free nature of the cured POLY FILLER HT paste provides for easier working with tools and prevents sand paper from becoming gummy. Once applied and cured, POLY FILLER HT will bond quite well to most surfaces such as aluminum, copper, fiber glass, epoxy, steel, plaster, graphite and kevlar laminates. It will also accept all types of enamel, epoxy, lacquer and paint stains as a surface finish. POLY FILLER HT utilizes an excel lent high temperature resin base, and therefore the cured paste can be subjected to service temperatures in excess of 400ºF. |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Specifications

- Color Available in Gray or Black Versions

- Viscosity, centipoise: Smooth, Thixotropic Paste

- Mix Ratio, By Weight: 100 Parts Resin : 2 Parts Cream Hardener, By Weight

- Pot Life, 4 fl. Oz. Mass @ 77ºF: 6 - 8 minutes

- Tack Free Time: 10 Minutes After Gel

- Time Before Sanding: 20 - 25 minutes After Gel

- Cured Hardness: 89 Shore D

Applications

- Aircraft High-Temp Bond Tools

- FRP Surface Patching

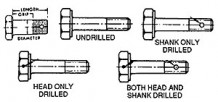

- Bonding Inserts and Bushings

- Honey comb Panel Edge Filling

- Crack, Crevice and Hole Repair

- Pattern Repair and Filling

- Core Box Repair

- RIM, BMC, SMC Surface Filling

- Fiber glass Boat Repair

- Router Fixture Repair

- Filling Porosity on Composites

- Vacuum Form Mold Repair

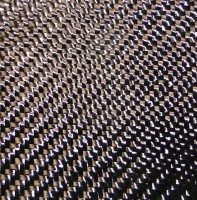

- Filling Cloth Texture Impressions

- Urethane Mold Repair

Documents

Reviews

this filler is excellent, allows to do quick patches locally to damaged molds. easy to mix, to apply and to sand. dries very quickly. the key feature is the high temperature capacity, 400F, so you may cure prepreg at 350F with plenty of margin.

Poly Filler HT is some pretty amazing filler material. trowels in smooth during working time, and provides the thin, feathered detailed edge and shape you want when hardened. Be prepared to put some muscle in to final finishing, its rock solid. Filling fine pinholes is a challenge realized after application. So work it, trowel it, press it, in when soft, to ensure no surprise holes left after hardening.

this filler works for its application but there are 3 major pitfalls : - the hardener is as black as the filler, so it is close to impossible to know when it it fully mixed. - the mix ratio is not trivial = 50:1 - the pot life is very short !! we measured 3 minutes at 80F, 5 minutes at 70F, 8 minutes at 50F this is a good product but challenging to mix and to apply. only for very small patches.

FREE Shipping

FREE Shipping