E-Mag P Model Ignition Lycoming

MFR Model# EMA01402

Overview

|

Note: New installation requires a harness, and possibly a gear, depending on the application (See Accessories). Verify requirements before ordering. If you are replacing a NON-IMPULSE magneto you can re-use the manufacturer's ignition drive gear from the old magneto. If you are replacing an IMPULSE magneto, those gears are a different style and cannot be re-used with the E-Mag and a Lycoming (or Superior) gear must be purchased. Lycoming 68C19622 gear: Part # 07-02011 Superior SL68C19622 gear: Part # 08-11837 Of all the E-MAG innovations, the self-powering capability of the "P" Model is the most significant. It solves the largest single issue faced by all electronic ignitions - their need for an uninterruptible power supply. Power back-up strategies that a) compromise ignition effectiveness, b) solve only half the problem, or c) require additional maintenance are less than ideal. Next-Generation ignitions need a better solution. So what does a next-generation electrical back-up need to do?

The P Model Built-In Alternator

Installing back-up batteries, together with switching circuits, to A) engage the back-up battery when needed, and possibly B) keep the back-up battery charged. This solution:

|

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Specifications

- Weight - roughly 3 pounds (naked - without drive gear and harness)

- Length - 6.25 inches measuring from the flange mounting face to the back of the plug harness.

Installation

Estimated Time: 2-4 Hours

1. Install Drive Gear: Recover the non-impulse drive gear from your old mag and install it on your E-MAG. If you don't have a suitable drive gear, E-MAG can provide one.

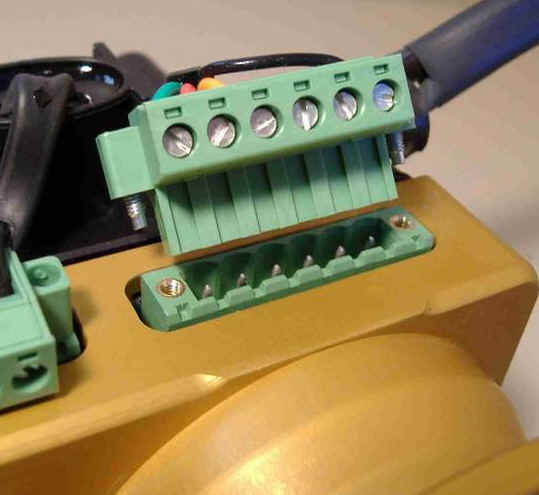

2. Connect Control Leads & Harness:

- Switch - Connect your existing ignition switch ("P Lead").

- Power - From your 12 volt power buss.

- Ground - Connect directly to engine case ground.

- Tach - (optional)

- MAP - Connect MAP sensor tube to fitting on ignition.

- Spark Plugs and Harness Kit

3. Install & Set Timing with Quick-Set TM:

- Pre-install the ignition(s) at any orientation that's convenient. You won't move them again so secure for operation. Position the engine at TDC.

- Power the ignition ON. Disconnect the MAP tubing where it ties into the craft and blow into it (minimum 1/2 psi for 1 second). The built-in LED will flash RED. Blow into the tube a second time and the LED will flash GREEN, indicating that timing has been set. Power cycle the ignition and your done.

Note: You can set timing on two E-MAGs in exactly the same way in exactly the same amount of time - 30 to 60 seconds.

Reviews

On the up-side, the P-mag is revolutionary aircraft engine security, self powered or ships power, with the enhanced benefit of radically more spark voltage resulting in more fuel burn per compression. With the right engine management, particularly in injected engines this can easily translate to more power and/or efficiency, and an easier route to running lean of peak as standard operating procedure, which is the biggest fuel savings Ive ever experienced in 23 years as a pilot. The recommended annual removal and inspection is a bummer, though. Ive yet to meet a mechanic who likes to take things off the accessory case and put them back on again if they dont have to, even though the re-timing of P-mags is quick and easy. This requirement is to check for play in the main bearing. If you find play, you have to send your unit in for rebuild, (now to the Maintenance Organization for Hartzell since they bought all of E-mag.) I bought this latest unit as a backup in case either of my P-mags has bearing play at annual, so I wont be grounded. Hartzell plans to develop the technology for certified use..... so watch for there to be a lot more of these in the GA fleet.

E-Mag P Model Ign With Alternator Lycoming 4

replaced a lightspeed plasma 3 that was almost 20 years old. The P-mag has been a marked improvement in starting and smoothness in cruise.

E-Mag P Model Ign With Alternator Lycoming 4

Have no need for this unit, as previously thought.

E-Mag P Model Ign With Alternator Lycoming 4

Best mag going for the RV8! Starts easy, runs smooth, and great power...

E-Mag P Model Ign With Alternator Lycoming 4

No problem.

E-Mag P Model Ign With Alternator Lycoming 4

P mag was delivered quickly . Back in the air.

E-Mag P Model Ign With Alternator Lycoming 4

I have 2 E-Mags running on an IO-360. Initial installation requires some patience, but great factory support. Advise installing a small 12v Li battery for starting and a recharging connection somewhere (jack on panel) to keep charged every couple of months. A cold weather start will draw main battery down too far for E-Mags so you need a tiny 12v battery dedicated with switch and 3A fuse. After 600 hours I start up in 2 revolutions every time. Never a problem. Simple timing procedure always impresses A&P.

Good price, quick, and good tracking.

This is a great product, but installation is more involved than is seams if you are replacing magnetos on a flying plane. You will likely need to add two switch’s to your panel, and if you are replacing an impulse magneto you need to replace the studs. Getting the correct fittings and hoses to connect the manafild pressure hoses can be a small project if you want to do it right. The kit comes with silicone rubber tubing.

Easy to install and time. Very reliable for 8 years. Runs better on one -mag than on 2 regular mags. I have two on my 0-360. No backup battery power needed with the built in alternator in the p-mag. I wish they were certified, too. I would put them on my J-35.

Q&A

Please note, Aircraft Spruce ®'s personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce ® assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

There is no application chart for this item with specific engine listings. However, per the manufacturer, it will work for most 4 cylinder Lycomings except dual single pad models, which would be known if that is the type you had.

Per the supplier: You'll want/need to use our harness with auto plugs. We stopped offering an aircraft harness back in 2010.

Per the supplier: No, you cannot use your old magneto harness or aircraft plugs.

Per the supplier: Currently, we only have ignitions for experimentals.

Per the manufacturer, their unit provides a safe amount of voltage for the ignition system.

Yes, it does.

The gear on an impulse type magneto will not work with this unit. You will need a non-impulse type gear (and shorter mounting studs) for each E-MAG install.

Yes. This will replace a slick mag.

This ships in a 12" x 8" x 8" box weighing about 4.25 lbs.

The gears on yoour slicks should work fine as long as they are still in good condition.

FREE Shipping

FREE Shipping