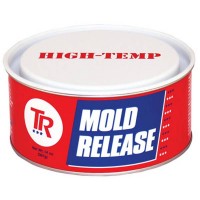

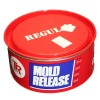

Tr-102 Regular Mold Release Paste 14 Oz

MFR Model# TR-102

| Model | Description | Size: | PN |

|---|---|---|---|

| TR-102 | A firm carnauba based mold release paste wax blended with other synthetic waxes for use in various thermo-set composite molding applications. | 14 oz. | 01-01598 |

Overview

On new or reconditioned tooling, suggest use of the sealer glaze TR-301 prior to waxing for added release, gloss and mold life. Apply wax with sponge applicator in thin even circular motion to the mold surface. Allow to haze dry (approx. 5-10 min) and polish wipe to gloss finish. For new or reconditioned molds apply a minimum of 6 coats of paste wax, waiting approx. 30-60 minutes between applications for the wax to harden after the polish wipe. Best results obtained if after application mold is allowed to stand overnight and a subsequent final coat of wax release applied following day prior to gel coating. Follow with a coat of wax for the first 2-3 parts released. Then determine how many parts can be effectively produced before re-waxing is required. This will vary depending on molding condition, configuration, resin, mold cycles, effective cure of production gel coat and other factors.

Uses:

|

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Features

TR-102:- High carnauba wax content polishes to high gloss without streaking

- Good heat and chemical resistance properties

- Easy application and wipe off characteristics

- Reduced wax build up and styrene accumulation

- Ease of application and removal. May be allowed to stand at length and still polish wipe easily

- Provides hard film with superior heat and chemical properties

- Polishes to high gloss without streaking

- Reduced wax build-up and styrene accumulation

Physical Properties

- Dry Time: 5-10 Minutes@ 72°F. Will Vary Depending On Working Temperature

- Wax Melting Or Softening Point: TR-102: 185°F (85°C) / TR-104: 185°F- 210°F (85°C- 99°C)

- Penetration Hardness: 1 At 25°C (Carnauba Wax)

- Color: TR-102: Off white / TR-104: Light Blue Tint (Color Coded For Identification) / TR-301: Colour colorless (in liquid state beige) consumption approx. 15 g / cm² per application solvent Water / petroleum distillate

Documents

Q&A

Please note, Aircraft Spruce ®'s personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce ® assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

It has a slight chemical smell but not strong or overpowering.

FREE Shipping

FREE Shipping