SAME DAY SHIPPING ON ORDERS PLACED BY 4 PM | 877-4-SPRUCE

Drill Pro Four Facet Drill Grinder

$1650.00/Each

Part# 12-04725

MFR Model# DRILL PRO

MFR Model# DRILL PRO

- JUMP TO

- Overview

- Features

- In The Box

- Reviews

- Q&A

Overview

|

This Drill Pro grinds 2" in diameter under two minutes. This Drill operates unattached on a tripodal support heavy-duty steel base and dynamically balanced motor. After nearly 21 years of expertise in the metalworkng business, McDonald Enterprises has become one of the most revered brands in metalworking tools today. McDonald Enterprises focuses on innovations to help the metalworker create masterpieces easier and with more precision. |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Features

- Grinds 2" dia. drill under two minutes.

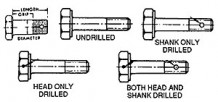

- Drill capacity: No. 60 to 3" dia. tapered or straight shank 2, 3 or 4 flutes.

- Accuracy: Actually equals or exceeds new drills.

- Portability: Operates unattached on a tripodal support heavy-duty

- Steel base and dynamically balanced motor. This includes a balanced wheel because of the design that permits dressing both the wheel face and side grinding rim (with the same dresser).

- The only grinding machine that grinds flat-faceted drills up to 3" diameter

- Locking System:

Drills into place using wheel’s rotational force on drills face, twists and locks drill into locating plate. No rotational movement. - Dual Bed System:

Lower support bed is adjustable and locks for lip clearance and drill point angles supports the detachable upper bed. - Screw Tip:

The thread tension bar is an adjustable locking type stop. - Lip Angle Extension Gage:

Extends an exact amount of drill point beyond the drill bed. Optimum extension is automatically accomplished when the cutting lip spirals into parallel alignment with its adjacent baffle line. - Boss System:

Operator oscillates the upper grinding mechanism back and forth across the grinding rim's full width. This permits finer finish yet faster, cooler grinding action with coarser wheels. Simultaneously, it eliminates wheel grooving minimizing heat, glazing and loading. As tools are ground across the rim, the wheel wears down on the same parallel plane. This constitutes automatic wheel dressing which increases diamond dresser and wheel life while allowing the operator to concentrate fully on the grinding operation.

In The Box

- 1/2 Hp Totally Enclosed Fan Cooled Motor Prewired for 110volt Operation

- Sharpening Mechanism

- Lip Angle Extension Guage

- Grinding wheel

- Instructions

FREE Shipping

FREE Shipping