FREE SHIPPING ON ORDERS OVER $350 (SOME EXCLUSIONS APPLY) | 877-4-SPRUCE

Tekton Deep Bite Round Jaw Locking Pliers

Select Length:

7 Inch

7 Inch 10 Inch

10 InchOverview

|

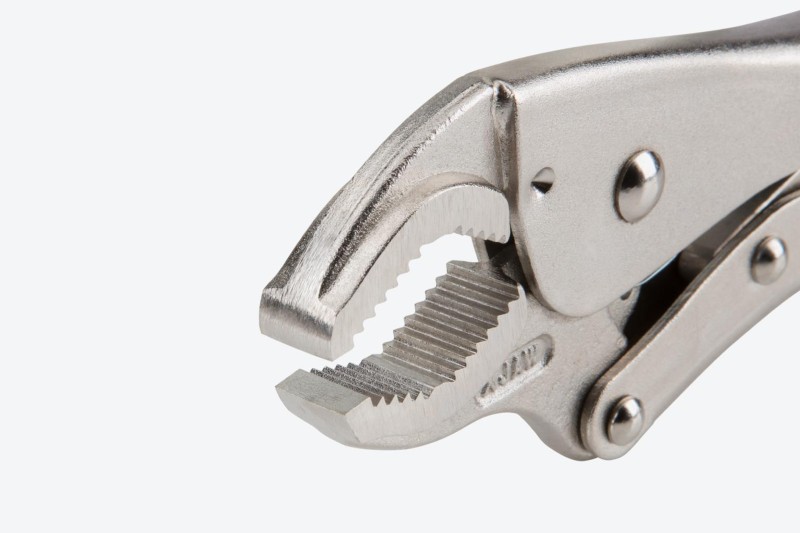

Deep Bite Round Jaw

The jaws are designed to encircle pipes, round fittings, and hex nuts and dig in with sharp teeth set at opposing angles. As the pliers close, the bottom jaw shifts forward setting the teeth into a strong directional bite, creating even higher clamping pressure. Pull-to-Release Lever Easily set, release, and reposition the clamp with one hand and with more control than a traditional pinch-style lever. Large Adjustment Knob The adjustment knob is knurled and round to provide grip for making adjustments even when you’re wearing gloves or have slippery hands.  Tensioning Through-Hole Get extra leverage and fine-tune your clamping force by inserting a screwdriver or hex key into the through-hole to create a T-handle.  High-Strength Rivets Three main rivets work together to make up the 4-point mechanical structure of the pliers and give it its strength. To make sure ours can withstand high shear forces, the rivets are made from tough 4135 chromium molybdenum steel.  Strong Jaws and Teeth The jaws are made from 4140 chromium molybdenum steel, an alloy that offers toughness, machinability, and corrosion resistance. The teeth are hardened to 45-50 HRC and should not chip or strip even on fasteners up to Grade 8 or Class 12.9.  Durable Nickel-Plated Finish Before assembly, the individual jaw, handle, lever, and crossbar parts are shot-peened to create smooth, consistent surfaces. The final finish is a durable nickel plating that protects against corrosion.  |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

FREE Shipping

FREE Shipping