3M™ AC-251 B-2 3.5 Oz - Canopy / Windshield Sealant

MFR Model# 7100133274

Overview

|

AC-251 Black Class B are two-part, quick curing, polysulfide based canopy and windshield sealants. These products are formulated for sealing acrylic, glass, and polycarbonate aircraft canopies and windshields. AC-251 Black Class B Sealants contain no solvent and do not craze. The sealants quickly cure and exhibit excellent adhesion and resistance to UV and weather exposure.

6 Oz Container with a 3.5oz Fill |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Features

- AC-251 Black Class B Sealants have a thixotropic, non-sag consistency

- They can be readily applied with a spatula or extrusion gun on vertical surfaces

Specifications

- MAT-587 Qualified (B-1/2,B-2)

Documents

Reviews

This stuff worked great sealing the windshield on my Cessna. Working time is a little less than 2 hours but if you’re properly setup, an hour is more than sufficient. I taped off the area, applied and smoothed the sealant, then peeled off the tape for a perfect finish. It came out great.

3M AC Tech AC-251 B-2 Windshield / Canopy Sealant - 3.5 Oz. Cartridge (Black)

3M AC Tech AC-251 B-2 Windshield / Canopy Sealant - 3.5 Oz. Cartridge (Black)

3M AC Tech AC-251 B-2 Windshield / Canopy Sealant - 3.5 Oz. Cartridge (Black)

Great product. You need a special caulking gun to accurately place the very thick solution on the windshield or in any crevasse/gaps. Be sure to properly mix the ingredients

3M AC Tech AC-251 B-2 Windshield / Canopy Sealant - 3.5 Oz. Cartridge (Black)

3M AC Tech AC-251 B-2 Windshield / Canopy Sealant - 3.5 Oz. Cartridge (Black)

Same results as another reviewer below. We prepped the surface very well and applied the sealant. Let it cure for about 5 days. The sealant strip started to separate from the aircraft during the first flight and just flopped around loose during flight. We very easily removed the remainder of it post flight just by pulling it off. It didnt stick to the surfaces at all.

Worthless on a Cessna. Cleaned and prepped IAW directions and had the entire top windshield strip come off and start beating the aircraft right on takeoff. Wont stick to lexan or aluminum. Save your money and use conventional windshield silicone.

Q&A

Please note, Aircraft Spruce ®'s personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce ® assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

The material is not considered haz-mat. The surface must be clean and free of any contamination. Primer is not required.

Per the tech data sheet in the Documents tab show the B-2 has a 2 hour working time. Please review the TDS for more details on this product.

That is tough to answer because the size of windshields would vary aircraft to aircraft. Most customers buy 2-3 when installing windows.

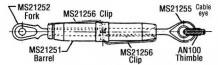

They would require a special extrusion gun to apply or you can use the included application tip. The gun part number would be 09-38520 for example.

Yes, this is a 6oz container with a 3.5oz fill.

FREE Shipping

FREE Shipping