HTR212/ H386-99 Laminating Resin

- JUMP TO

- Overview

- Documents

- Reviews

- Q&A

- View in Catalog

Overview

|

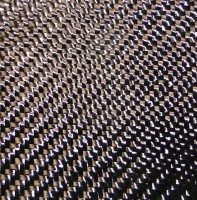

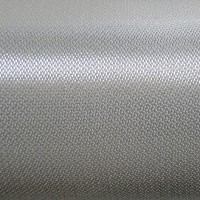

RATIO: 100 pbw to 33 pbw DLRH-3212 is an unfilled, clean epoxy resin system with a long pot life. DLRH-3212 is a tough, strong, impact resistant resin with chemical resistance. It has excellent wetting quality on kevlar, carbon graphite and fiberglass cloth. Used extensively in construction of aircraft, race cars, motorcycles, helmets and sports equipment. Mixing Ratio by Wt: 100:30; Pot Life (200 Gm MASS) 60 Min; Tensile Strength @ 25 C 12,500; Flexural Modulus @ 25 C 40,900; Heat Deflection 325 F; Thermal Shock 72°F–125°F; Shore “D”: 80, Density: Resin: 9.7, Hardener: 7.9, Mixed: 9.1; Shelf Life: Resin/ Hardener 1 Year.

|

||||||||

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Documents

Reviews

Use for making Engine plenum. Call to Mfr they insist on post cure of 50F rise per hr until 300F, then back to room temp to get the full Hi Temp capability. Thick like honey, but still wets very well. Very slow to cure, need to have heat lamps or heater to help cure. Will take 24hrs for sure even with heat lamps. Get heat lamps from chicken section at TSC! They Work great!!!

HtR212/H386-99 Resin Quart

Great online catalog. Easy to use. Fast delivery.

I use this resin extensively throughout our mid-sized UAV. I have always preferred MGS 285, but HTR works great for most parts and wets out almost as well. Unfortunately no choice of hardeners. Pot life is just long enough to layup wing-skins or thick, complicated carbon components Maybe 1hr tops before closing the mold or pulling vacuum. I really love the high temp resistance of this resin compared to MGS. Need to debond a fitting or joint? Hit it with the heat gun and pull it apart. The HTR part is uneffected, while West sys, 3M DP420 and others turn to putty. Simply put A pleasure to work with!

FREE Shipping

FREE Shipping