This polish is amazing. Will never use anything else!

Craig S

Verified Purchase

Verified Purchase

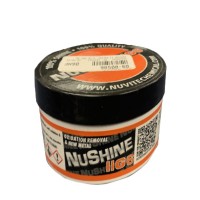

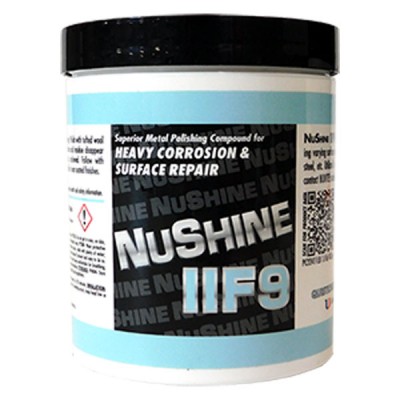

Nu-Shine Polish 1/2 Lb Grade S

January 6, 2026

Mitch W

Verified Purchase

Verified Purchase

Nu-Shine Polish 1/2 Lb Grade S

November 7, 2025

communication and product delivery was excellent

Mike M

Verified Purchase

Verified Purchase

Nu-Shine II Small 1 Lb

November 5, 2025

The warbird engine cowling came up like a mirror in just half a game a football, curved cowling with manufacturing marks and lines just disappear in these 3 steps. I highly recommend this for any aluminum or metal polish on your aircraft.

Flying C

Verified Purchase

Verified Purchase

Nushine II 1/2Lb Polish Grd C

September 4, 2025

The warbird engine cowling came up like a mirror in just half a game a football, curved cowling with manufacturing marks and lines just disappear in these 3 steps. I highly recommend this for any aluminum or metal polish on your aircraft.

Flying C

Verified Purchase

Verified Purchase

Nushine II 1/4 Polish Grade S

September 4, 2025

The warbird engine cowling came up like a mirror in just half a game a football, curved cowling with manufacturing marks and lines just disappear in these 3 steps. I highly recommend this for any aluminum or metal polish on your aircraft.

Flying C

Verified Purchase

Verified Purchase

Nushine II Grade F7 1/4Lb

September 4, 2025

Worked great on our older airstream to shine her up. This product is the first step in a three step process.

Gregory A

Verified Purchase

Verified Purchase

Nushine II Grade F7 1/4Lb

August 28, 2025

Ive tried them all on my polished 47 140. There is not another polish on the planet that performs as well or leave a nicer finish. Hands down this is the best out there.

James P

July 17, 2025

William S

Verified Purchase

Verified Purchase

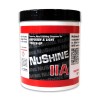

Nushine II Grade A 1/4Lb

July 15, 2025

Fantastic product. Works exceptionally well.

Kenneth S

Verified Purchase

Verified Purchase

Nushine II C 1Lb

July 10, 2025

These are great polishes for polishing aluminum.

Jc C

Verified Purchase

Verified Purchase

Nushine II 1Lb Grade A

June 25, 2025

These are great polishes for polishing aluminum.

Jc C

Verified Purchase

Verified Purchase

Nu-Shine II Small 1 Lb

June 25, 2025

We polish acres of of aluminum using this system with great results, eventually emptying the containers. We also have selves full of (various) partially used polishing products that just dont work as well.

Aloft A

Verified Purchase

Verified Purchase

Nushine II 1/4 Polish Grade S

February 12, 2025

We polish acres of of aluminum using this system with great results, eventually emptying the containers. We also have selves full of (various) partially used polishing products that just dont work as well.

Aloft A

Verified Purchase

Verified Purchase

Nushine II Polish A 1/2 Lb

February 12, 2025

Roger E

Verified Purchase

Verified Purchase

Nu-Shine II Small 1 Lb

December 6, 2024

Retchie T

Verified Purchase

Verified Purchase

Nu-Shine II Small 1 Lb

July 16, 2024

Retchie T

Verified Purchase

Verified Purchase

Nushine II C 1Lb

July 16, 2024

works well

Dennis L

Verified Purchase

Verified Purchase

Nu-Shine II Small 1 Lb

July 10, 2024

works well

Dennis L

Verified Purchase

Verified Purchase

Nushine II C 1Lb

July 10, 2024

Works great on an Airstream

Stan C

Verified Purchase

Verified Purchase

Nu-Shine II Small 1 Lb

May 8, 2024

I used this to shine up an airstream trailer. Worked great.

John C

Verified Purchase

Verified Purchase

Nushine II C 1Lb

April 26, 2024

Korey E

Verified Purchase

Verified Purchase

Nushine II 1Lb Grade A

January 25, 2024

This was the finishing touch for our 1961 Nomad trailer and brought back a great shine to tired aluminum. JR

John R

Verified Purchase

Verified Purchase

Nushine II Polish A 1/2 Lb

October 17, 2023

Works as advertised. I great first step for what I had going on.

John W

Verified Purchase

Verified Purchase

Nushine II Grade F7 1/4Lb

August 18, 2023

Great stuff. Makes me want to enter my plane in a show competition.

John W

Verified Purchase

Verified Purchase

Nu-Shine Polish 1/2 Lb Grade S

August 18, 2023

NuVite works great! It’s a lot easier than using Metall like I’ve done in the past.

John W

Verified Purchase

Verified Purchase

Nushine II C 1Lb

August 18, 2023

Fsc

Verified Purchase

Verified Purchase

Nu-Shine II Small 1 Lb

July 16, 2023

Fsc

Verified Purchase

Verified Purchase

Nushine II C 1Lb

July 16, 2023

Fsc

Verified Purchase

Verified Purchase

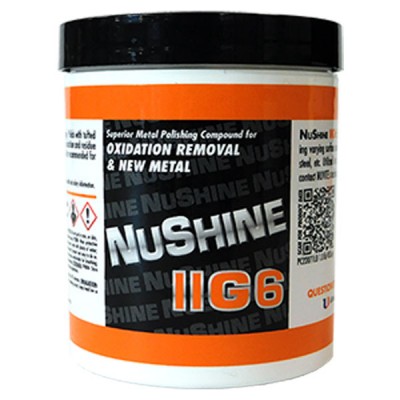

Nushine II Grade G6 1Lb

July 16, 2023

Fsc

Verified Purchase

Verified Purchase

Nushine II Polish G F7 1/2 Lb

July 16, 2023

Been using it for 6 years. I highly recommend it on Aluminium

Ken L

Verified Purchase

Verified Purchase

Nushine II C 1Lb

June 15, 2023

Great Stuff, I give it 10 out of 10. Does what it ssays on the tin.

Ken L

Verified Purchase

Verified Purchase

Nushine II Polish G F7 1Lb

June 15, 2023

If you want some super shiny aluminum use Nu-Shine. You will be blinded by shinny airplanes.

Alaska A

Verified Purchase

Verified Purchase

Nushine II 1/2Lb Polish Grd C

June 3, 2023

Ken L

Verified Purchase

Verified Purchase

Nushine II C 1Lb

May 30, 2023

Ken L

Verified Purchase

Verified Purchase

Nushine II Polish G F7 1Lb

May 30, 2023

Ken L

Verified Purchase

Verified Purchase

Nushine II Polish G F7 1Lb

May 30, 2023

I ordered the product thinking I would get what the picture showed, which was a 1 lb. tub. What was sent was a 1/4 lb.. yes the print did say 1/4. They requested that I return for a refund but I would have to pay the shipping.

Terry G

Verified Purchase

Verified Purchase

Nushine II 1/4 Polish Grade S

May 23, 2023

I am using the Nuvite polish system on my Zenith 601. I started with the F7, now the IIC and will do the IIA later. So far I am very happy with the results. I have a shiny, classy airplane using a process that is very much cheaper and a lot lighter that paint. The downsides are that its a lot of work and the work will be ongoing. I have no regrets and stronger shoulder muscles

Alex M

Verified Purchase

Verified Purchase

Nushine II C 1Lb

May 12, 2023

Good product to use

Perry T

Verified Purchase

Verified Purchase

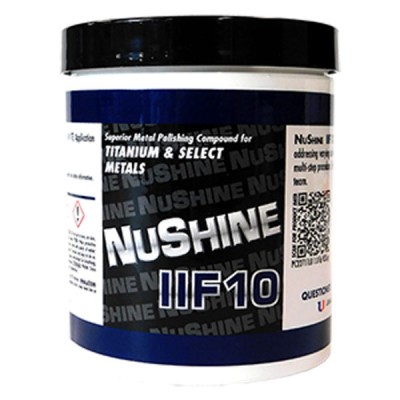

Nushine II Grade F10 1/2Lb

April 19, 2023

Good product

Perry T

Verified Purchase

Verified Purchase

Nushine II Grade F9 1Lb

April 18, 2023

Great product for our

Restoration project !

Kim H

Verified Purchase

Verified Purchase

Nushine II C 1Lb

April 18, 2023

Very good

Massimiliano B

Verified Purchase

Verified Purchase

Nu-Shine II Small 1 Lb

March 21, 2023

Very good

Massimiliano B

Verified Purchase

Verified Purchase

Nushine II C 1Lb

March 21, 2023

Very good

Massimiliano B

Verified Purchase

Verified Purchase

Nushine II Grade F9 1Lb

March 21, 2023

This polish is totally awesome.

William M

Verified Purchase

Verified Purchase

Nushine II Grade G6 1/4Lb

February 22, 2023

This polish is totally awesome.

William M

Verified Purchase

Verified Purchase

Nushine II Grade A 1/4Lb

February 22, 2023

Rigo M

Verified Purchase

Verified Purchase

Nu-Shine Polish 1/2 Lb Grade S

February 1, 2023

Rigo M

Verified Purchase

Verified Purchase

Nushine II C 1Lb

February 1, 2023

Works well to remove exhaust tarnish on stainless exhaust (power flow).

Final A

Verified Purchase

Verified Purchase

Nushine II Grade F7 1/4Lb

January 21, 2023

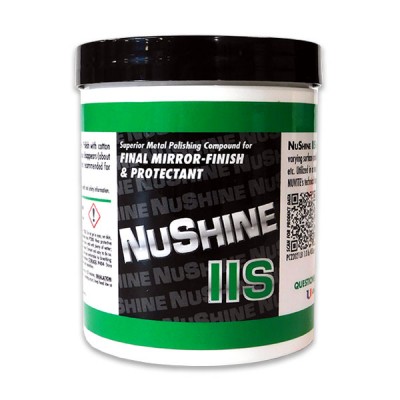

This is a great product, used it on my 1975 airstream tradewind for protecting my polish. It protects and also brings back the mirror polish back. I use this polish as a wax , to protect the bare aluminum from oxidation.

Ross R

Verified Purchase

Verified Purchase

Nu-Shine II Small 1 Lb

November 4, 2022

Leroy B

Verified Purchase

Verified Purchase

Nu-Shine Polish 1/2 Lb Grade S

October 31, 2022

This is the first compound I use to remove metal and get the start of a shine.

Richard J

Verified Purchase

Verified Purchase

Nushine II Grade G6 1Lb

October 21, 2022

Good heavy duty polish for aluminum.

Tyler S

Verified Purchase

Verified Purchase

Nushine II Polish G F7 1Lb

July 5, 2022

Good medium grit polish for aluminum.

Tyler S

Verified Purchase

Verified Purchase

Nushine II C 1Lb

July 5, 2022

Gayland T

Verified Purchase

Verified Purchase

Nushine II Grade A 1/4Lb

June 14, 2022

Good item

Gayland T

Verified Purchase

Verified Purchase

Nushine II Grade G6 1/4Lb

June 14, 2022

Works well on my Sonex!

William A

Verified Purchase

Verified Purchase

Nu-Shine Polish 1/2 Lb Grade S

May 13, 2022

Nu-Shine is the only product to use to get a mirror finish on aluminum and Aircraft Spruce is the only supplier to use. Used to buy from Aircraft Spruce when I worked for Dassault Falcon Jet. Retired now and now polish my boat.

William G

Verified Purchase

Verified Purchase

Nu-Shine II Small 1 Lb

May 4, 2022

Stephen W

Verified Purchase

Verified Purchase

Nushine II Grade A 1/4Lb

April 20, 2022

Great product!

Monroe B

Verified Purchase

Verified Purchase

Nushine II 1/2Lb Polish Grd C

April 5, 2022

Great product!

Monroe B

Verified Purchase

Verified Purchase

Nushine II 1/4 Polish Grade S

April 5, 2022

Great product!

Monroe B

Verified Purchase

Verified Purchase

Nushine II Grade F7 1/4Lb

April 5, 2022

The Grade C compound is a product that I can’t live without . It is amazing and you won’t understand until you need it and don’t have it . I assure you . When they state how the product should be used , they aren’t kidding when they say it . The procedure’s that they give will give you the flawless results you are looking for . I have experienced it all from quick jobs with ok results , to slowing right down and taking my time . When you take your time you will be smiling just like I did . Thank you all for the know how twos . Unbelievable product .

Luke S

Verified Purchase

Verified Purchase

Nushine II C 1Lb

March 19, 2022

Outstanding product.

Gary R

Verified Purchase

Verified Purchase

Nu-Shine II Small 1 Lb

March 18, 2022

Great product. I have used the Nuvite line to bring my bare aluminum C-195 up to a sparkling jewel.

Rob I

Verified Purchase

Verified Purchase

Nushine II Polish A 1/2 Lb

March 17, 2022

David R

Verified Purchase

Verified Purchase

Nushine II Polish .5 Lb Grd G6

March 8, 2022

Dennis E

Verified Purchase

Verified Purchase

Nu-Shine II Small 1 Lb

January 31, 2022

Tom G

Verified Purchase

Verified Purchase

Nu-Shine II Small 1 Lb

December 18, 2021

Great product

Tom G

Verified Purchase

Verified Purchase

Nushine II Polish G F7 1Lb

December 18, 2021

This works great for brightwork. Also Aircraft Spruce has the best prices around for this product.

Karli B

Verified Purchase

Verified Purchase

Nushine II Grade G6 1Lb

November 27, 2021

This works great for brightwork. Also Aircraft Spruce has the best prices around for this product.

Karli B

Verified Purchase

Verified Purchase

Nu-Shine II Small 1 Lb

November 27, 2021

Excellent product. Leaves a mirror finish.

Joshua K

Verified Purchase

Verified Purchase

Nu-Shine II Small 1 Lb

November 10, 2021

I used F10 to polish out deep repair scratch marks on my polished aluminum cowling. The F10 preformed great and removed the marks in far fewer polishing passes than anticipated. I highly recommend F10. Larry Smith

Larry J

Verified Purchase

Verified Purchase

Nushine II Grade F10 1/2Lb

October 10, 2021

Dwain R

Verified Purchase

Verified Purchase

Nu-Shine II Small 1 Lb

October 1, 2021

Dwain R

Verified Purchase

Verified Purchase

Nushine II 1Lb Grade A

October 1, 2021

Dwain R

Verified Purchase

Verified Purchase

Nushine II 1Lb Grade A

October 1, 2021

Lois D

Verified Purchase

Verified Purchase

Nushine II 1Lb Grade A

July 31, 2021

Great product but I found out early that I should have started with a little tougher grit as the vintage camper Im polishing has some scratches - so I ordered more and am anxious to get started. Even the 2 grades (C & S) that I ordered first did an amazing job on the small area I did. The bare aluminum is pretty close to a mirror finish. Im looking forward to seeing what the next order can do for her.

Joann S

Verified Purchase

Verified Purchase

Nu-Shine Polish 1/2 Lb Grade S

June 17, 2021

WOW! I am using this on a vintage camper - bare aluminum, never painted but after 61 years shes shinning in the sun. It does make her dimples show up but its cleaned all the dull oxidation off and left a beautiful shine.

Joann S

Verified Purchase

Verified Purchase

Nushine II 1/2Lb Polish Grd C

June 17, 2021

Great product.

Don G

Verified Purchase

Verified Purchase

Nushine II C 1Lb

June 8, 2021

Did a fine job on my 1961 Airstream

R J

May 18, 2021

Fast delivery with certs and full shelf life!

Fly R

January 11, 2021

Works great

Marc M

October 5, 2020

Speedy service

David C

October 2, 2020

Great!

David L

September 26, 2020

delivered on time. I think delivery cost was a bit high

Gene D

August 18, 2020

Worked well, very fast service. Received within a week of ordering.

Angelene P

July 16, 2020

Excellent product! Great customer service. Very fast shipping too!

Aaron T

July 10, 2020

INCREDIBLE STUFF!!

L G

June 29, 2020

Works great. Helped shine my pontoons fairly well. Pilot shop has amazing customer service as well. Would never hesitate to buy from here again!

Jon

June 23, 2020

Great stuff! Turn aluminum into chrome (just about)

Steve R

May 28, 2020

The nuvite line of polishes is ideal for polishing Aluminum or other metals. You can bring a very dull piece up to a high gloss. You need to look at the Nuvite tutorial on line to make sure you are using the proper techniques. I have maitained the polish on my RV9a for 7 years now. Only do a complete polish evry 2 years or so. Just touch up ocasionally. A little goes a long ways. You need a variable speed rotary buffer for all the grades accept S. For S I use the double headed random orbital polisher offered by nuvite. By the way, it is also sold by Aircraft Spruce. Great Products. I dont know of anything that would substitute.

John O

March 19, 2020

Na

Rolland W

January 12, 2020

Your project may require some sanding first like mine. When you use this after getting the pitting and corrosion out with sand paper, the metal comes out looking like a mirror! Its a little bit expensive, but its worth spending the money.

Joshua

August 16, 2019

A bit of a work to polish it, but best deep shine so far!

Uek

August 10, 2017

Very arduous to polish, but best result, tested against other brands. Can recommend it

Uek

August 10, 2017

Start with grade C, finish with grade S. This product produces a deep mirror finish on aluminum that is unmatched by any other product. We have used it on spinners, pitot tubes, turbine inlet barrels, and trim work.

Griswold A

July 12, 2013

Sebastien L

Verified Purchase

Verified Purchase

Nu-Shine II Small 1 Lb

October 21, 2025

If you’re polishing and old Airstream you need this stuff

John B

Verified Purchase

Verified Purchase

Nushine II Grade F9 1Lb

June 12, 2024

Overall a good product, it’s aviation, so it’s priced high.

Jeffrey V

Verified Purchase

Verified Purchase

Nu-Shine Polish 1/2 Lb Grade S

March 14, 2022

Overall a good product, it’s aviation, so it’s priced high.

Jeffrey V

Verified Purchase

Verified Purchase

Nushine II 1/2Lb Polish Grd C

March 14, 2022

Éric G

Verified Purchase

Verified Purchase

Nu-Shine Polish 1/2 Lb Grade S

May 29, 2025

more info about cleaning surface first would be nice.

Dennis L

Verified Purchase

Verified Purchase

Nushine II Grade F7 1/4Lb

May 3, 2024

works ok more info would be nice.

Dennis L

Verified Purchase

Verified Purchase

Nu-Shine Polish 1/2 Lb Grade S

May 3, 2024

it works ,should more info.

Dennis L

Verified Purchase

Verified Purchase

Nushine II C 1Lb

May 3, 2024

Have not received. No tracking.

Mel R

October 14, 2019

I like Nuvite products, but this grade did not live up to its hype.

Brian C

April 17, 2017

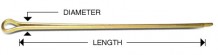

A

A F7

F7 F9

F9 G6

G6 F10

F10 C

C S

S

FREE Shipping

FREE Shipping