Engine Right Angle Drive

- JUMP TO

- Overview

- Reviews

- Q&A

- View in Catalog

Overview

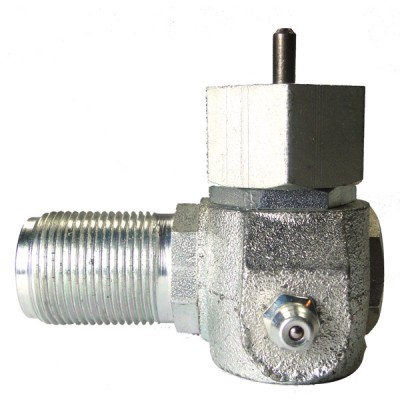

| Female end attaches to engine tach drive outlet. Male out- put end accepts standard tach cable female nut (7/8-18 straight thread). Eliminates bending of tach cable at the engine in cramped installations. Designed for heavy-duty service. Gears and shafts are of heat-treated alloy steel.Oil impreg-nated sintered bronze shaft bearings. Cast iron case and fittings. With lubricator fitting for greasing. 1:1 ratio. |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Reviews

Worked as expected.

Engine Right Angle 1:1 A-1111

Engine Right Angle 1:1 A-1111

Worked perfect! Used for connecting AN 5531-1 tach generator to a PW 1340-AN-1.

Engine Right Angle 1:1 A-1111

It fits well. It has a grease fitting but no hint on how often the fitting needs to be serviced.

Engine Right Angle 1:1 A-1111

Engine Right Angle 1:1 A-1111

This was a very easy install, it wasnt going the correct direction at first but all I had to do was simply put a wrench on it and transfer the barrel to the other side and it worked like a champ. Bullet proof too, and with a grease nipple as well. Very nice, the only possible way for them to make it better would have been for them to reach out and install it FOR me.

Engine Right Angle 1:1 A-1111

Works as described

Engine Right Angle 1:1 A-1111

Adapts to engine only, not tach.

Engine Right Angle 1:1 A-1111

I bought it to use on a Ford tractor, Ford dealer wanted three times the price for basically the same thing. We were able to take this tach drive apart to reverse the direction and so far it works awesome.

The perfect solution to a difficult installation problem The Tach cable now passes through the firewall with a gentle turn - no more broken cables at the tight bend

Q&A

Please note, Aircraft Spruce ®'s personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce ® assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

Yes, you would just need to switch the tach cable end fitting to the other side of the unit and it will change the direction of the rotation.

Per supplier: This right angle drive has one end that has the key/tang that goes in the drive and a nut to secure it to the tach drive on the engine, and the other end at 90* to attach the tach cable that has the key/tang that would normally go in the drive, and a nut to secure it. The thread size is 7/8-18.

The grease nipple will have no threads on it. This will have a .263" OD of the largest point on the grease nipple.

2.641" long, 2.205" wide, 1.87" tall.

It does not reverse the rotation.

Yes the nut spins free allowing the adapter to be "clocked."

FREE Shipping

FREE Shipping