Met-L-Chek Developer D-70

MFR Model# M-D-70-16

Overview

|

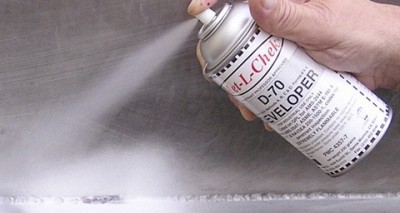

D-70 has been used by automotive manufacturers to assist in locating oil and gas leaks in engine components and hydraulic lines. The area of interest is cleaned and the developer applied. The engine is run and the oil leak will appear as a dark spot on the white coating. Reminiscent of the old oil and whiting inspection used by railroads before the advent of modern penetrant inspection materials.

The use of a developer is required by most penetrant inspection testing specifications. The developer draws the penetrant from the flaw and creates a uniform surface on which to view the penetrant indication. D-70 is used with fluorescent penetrants as form "d" and with visible penetrants as form "e". It is applied after the surface penetrant has been removed and the inspection surface dried. D-70 nonaqeous developer consists of absorbent powder suspended in a volatile solvent. The developer particles will settle out upon standing, requiring agitation prior to application. This type of developer is most commonly used in aerosol cans, but may also be bulk sprayed using a paint sprayer. The solvent action of this type of developer helps bring the penetrant to the surface enhancing the detectability of the finest flaws. This type of developer uses flammable solvents and should not be used in confined spaces or near open flames or sparks. D-70 is approved by Boeing, Edf, GE, Pratt & Whitney, ISO- 3452-2005 and is the qualification standard for AMS-2644E. It is low in Sulfur, Sodium, Chlorine, Fluorine and other Halogens, making it safe for use on Titanium and high Nickel alloys found in aerospace, medical and nuclear components. D-70 finds wide use in weld inspection in ship building and weld repairs. It is used in heat exchanger inspection in what is called the through leak method where penetrant is applied to one side and the D-70 to the other. After a prescribed penetration time the developer coating is inspected for penetrant indications which highlight a through leak. |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Physical Properties

- Form: milky liquid

- Density: 851 g/L

- Flash Point: 11.6°C (54°F)

- Fluorescence: none

- Dry Coating: smooth white

- Removability with water: complete

- Corrosion of aluminum: none

- Corrosion of carbon steel: none

- Corrosion of magnesium: none

- Corrosion of stainless steel: none

- Corrosion of titanium: none

- Chloride content: < 150 ppm (0.015%)

- Fluoride content: < 50 ppm (0.005%)

- Sodium content: < 350 ppm (0.035%)

- Sulfur content: < 200 ppm (0.02%)

- Mercury: none

- VOC's: 710 g/L

- Ozone layer depleting substances: none

- PCB's: none

Specifications

- AMS-2644E

- AMS-2647C

- ASME B & PV code 07 sec V

- ASTM E-165

- ASTM E-1417

- ISO-3452-2005

- PMC-4357-7

- RR CSS-232

- RCC-M rev 2000

- Snecma DMC0010 rev J

Documents

Click Here for MSDSReviews

D-70 Developer Mil-I-25135E

Does what its suppose to do, detects cracks.

D-70 Developer Mil-I-25135E

Chased an oil leak for a couple months. Sprayed the Developer on and found a seeping crack in the cylinder in 5 minutes of run time.

D-70 Developer Mil-I-25135E

it does what it is suppose to do

D-70 Developer Mil-I-25135E

D-70 Developer Mil-I-25135E

D-70 Developer Mil-I-25135E

I know of no other product out there that works so well for finding leaks. I use it both for fuel leaks and also for water leaks. It’s great for finding small leaks and also pinpointing where the larger leaks are actually coming in for him. You won’t be disappointed.

D-70 Developer Mil-I-25135E

Works great, follow the directions.

D-70 Developer Mil-I-25135E

My techs save a ton of time identifying leaks on automotive products using D70. Worth every penny. My old source for D70 went out of business so I was very glad to find Aircraft Spruce as a new source.

D-70 Developer Mil-I-25135E

Q&A

Please note, Aircraft Spruce ®'s personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce ® assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

FREE Shipping

FREE Shipping