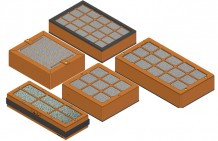

Engine Overhaul Stand Adapter

MFR Model# 13013

Overview

| Adapter for Continental and Lycoming engine overhaul stand. |

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov. |

Reviews

Engine Overhaul Stand Adapter

Great

Engine Overhaul Stand Adapter

Engine Overhaul Stand Adapter

I dont know why I thought this item was made of steel, but I did. Figured all I would have to do was weld it to a nice heavy piece of drill stem and I would have a motor stand. But NO..... this item is made of virgin white nylon! It did, however, make a dandy template to use to trace its outline on a piece of 1/2 plate to cut with a plasma cutter, grind, drill, smooth and finish to then weld onto said piece of drill stem. It will go in between the 1/2 steel plate and the crank of my Lycoming O-320.

I am a bit disappointed. I don’t know what engines this will fit but it won’t fit an O540 prop flange. The slots are too narrow. I will bore it out myself. I could have made one for myself with the effort it will take.

Q&A

Please note, Aircraft Spruce ®'s personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce ® assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

It is a type of durable plastic. The previous units were made of wood, but this material is more durable.

If you order a complete engine stand, this will be included. It has a SAE prop bolt spacing for Continental and Lycoming engines.

The stand only had two holes in it, you would attach this to the stand, and then attach the engine to this adapter.

Approx 3/4.

FREE Shipping

FREE Shipping